CASE STUDY: MUNICIPAL WASTEWATER

FORSTA SOLVES DIFFICULT SECONDARY EFFLUENT FILTRATION PROBLEM FOR CITY OF CARSLBAD, CA RESTORES WATER RECYCLING SYSTEM FOR PRODUCTION OF NON-POTABLE WATER FOR IRRIGATION

BACKGROUND: Municipalities Collaborate for Wastewater Reuse and Efficiency

The Encina Wastewater Authority (EWA) is a public agency located in Carlsbad, California. EWA provides wastewater treatment services to more than 400,000 residents in northwestern San Diego County. EWA’s facilities and services are essential for protecting the local ocean environment, preserving public health, and providing valuable water resources for the region.

EWA is owned by six public agencies governed by a Joint Powers Agreement. Under this Agreement, owners share in the operational and management costs of EWA, the objective being to cooperatively fund economical and high-tech facilities. The six owners are: the City of Carlsbad, City of Vista, City of Encinitas , Vallecitos Water District, Buena Sanitation District, and the Leucadia Wastewater District.

Founded in 1961, the EWA operates and maintains the Encina Joint Sewerage System which includes the Encina Water Pollution Control Facility, The Encina Ocean Outfall, The Agua Hedionda and Buena Vista Pump Stations.

EWA also manages and operates other regional water recycling and pumping facilities for their owners, including the Carlsbad Water Reclamation Facility, Buena Creek Pump Station, and the Raceway Basin Pump Station. The EWA System represents a significant infrastructure investment. Since 1980, the members of the Joint Powers Authority have invested over $600 million to protect the economy and quality of life for North County residents and businesses.

In September of 2016, the EWA commissioned a new 3.38 MGD Recycled Water System. The new system would process secondary effluent through a UF membrane system at the Carslbad Water Reclamation Facility and provide the treated effluent from the facility for local irrigation/land application. Local golf-courses, parks, and landscapes would no longer need to rely on potable water for irrigation.

According to the City of Carlsbad, each gallon of recycled water that is used to irrigate parks, street medians, freeway landscaping and golf courses saves a gallon of drinking water. A gallon of recycled water is also about 16 percent cheaper than a gallon of potable water, because the city controls the production.

The City of Carlsbad has approximately 79 miles of recycled distribution pipeline which currently supplies more than 700 recycled points of connection.

NEW SYSTEM DESIGN & COMMISSIONING: Equipment Compatibility Critical for Success

The new Recycled Water/UF membrane system was designed with 200 micron mesh pre-strainers for protection of the UF membranes. Prefiltration ahead of UF membranes prolongs the life of the system; by protecting it from an excess of suspended solids.

The pre-strainers selected for the Carlsbad job had multiple mesh wire candles, and would theoretically utilize a fluid reversal mechanism for automatic backwashing.

Within two weeks of the completion of the system commissioning (October, 2016), the pre-strainers presented operational problems. The fluid reversal mechanism that was intended to clean the strainer screens did not relieve the accumulated differential pressure. The strainers had to be disassembled at that time for inspection and manual cleaning.

Disassembly of the units required a cherry picker forklift and a complete system shutdown. Start-tofinish, the maintenance intervention took approximately 3 hrs. Review of the strainers’ multiple candle elements showed that the flow reversal technology was not sufficient to remove the sticky debris that characterized the plant’s secondary effluent.

Once disassembled, the strainer candles had to be individually power-washed in order to resume system operation.

After the first power-wash intervention, the strainers became ineffective within a few days, differential pressure was not relieved, and the 3-hr system shutdown and manual intervention had to be repeated. The pattern continued and required that the commissioning OEM provide manual cleaning twice per week.

In November, the strainer rep was brought onsite to conduct an installation review. During the visit, the strainer rep indicated that the mechanical function of the equipment was intact, and that the faulty cleaning in the installation had to do with chemistry. The strainer company provided no further support, indicating that issues of chemistry were beyond the scope of their work.

An immediate consequence of the malfunctioning strainers was that overall system flow had to be dropped to 66% or 2/3 of normal flow. If not for this imposed flow reduction, the manual power-wash intervention would have been required daily. The ongoing consequence amounted to ~1 day per week (2 half-days) of manual service at a cost of approx. $1200/day, for a period of nine months. The cumulative cost of troubleshooting in the tens-of-thousands fell to the OEM.

PROBLEM SOLVING: Suction Scanning Filter Outperforms Candlestick Backwash Strainer

By January of 2017, plans were set in motion to run a pilot for replacement equipment to finally reject the failed strainers.

The Encina Wastewater Authority needed a lasting solution to the equipment failure of the rejected strainers.

In February at the AWWA Membrane Technology Association conference of 2017 in Long Beach, CA the OEM responsible for the Carlsbad UF System became acquainted with Forsta technology. Forsta engineers learned of the problems encountered at the Carlsbad facility, and were confident they could provide equipment that would hold up to the operating conditions and provide reliable long-term service.

After consultation, the OEM brought on Forsta to assist in conducting a 3-month pilot system to verify the efficacy of Forsta’s design to solve the problems encountered with the rejected strainers. Understandably, the city wanted reliable pilot results before approving selection of replacement equipment. Of particular concern was the sticky material that had clung to the original strainer candle elements.

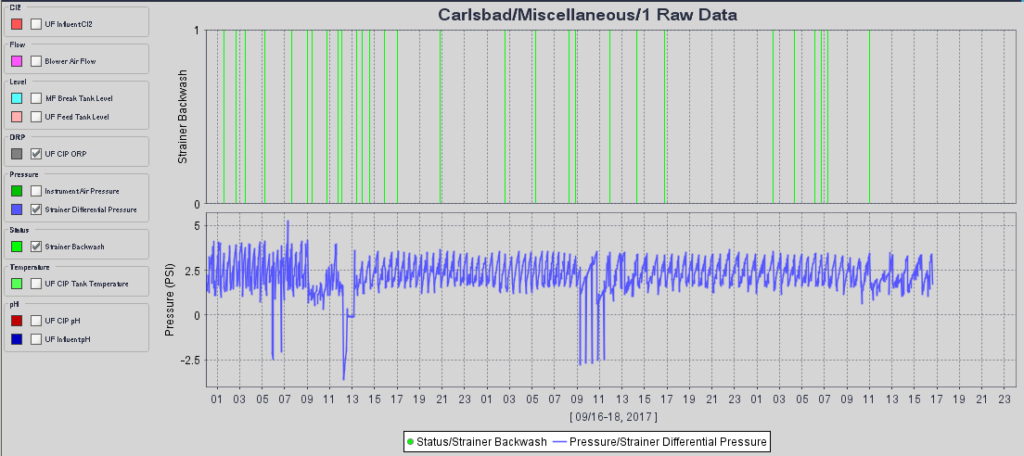

The pilot, which began in April of 2017 was designed to handle ~100gpm of the secondary effluent with a 200 micron mesh screen. Pilot data included; time for the filter to accumulate differential pressure, number of total backwashes in a given period, and the ability of the backwash to fully relieve differential pressure.

3-months of backwash monitoring validated Forsta’s design & technology for the scaled up version. During the pilot monitoring period, differential pressure was consistently relieved by the automatic backwash sequence, and suction scanning reliably removed all visible debris for ~800 consecutive backwashes.

One other technology was under consideration during the pilot phase. It was rejected in favor of the Forsta model, due to lack of performance during the pilot, painted carbon steel construction vs. the stainless construction of the Forsta model, and very lengthy lead times resulting from overseas manufacturing.

Installation and start-up were conducted with the full-scale Forsta suction scanners in July of 2017.

Forsta spent the next few months monitoring the installation closely with the OEM and onsite operations staff. Forsta’s design theory – simplicity – allows any technical issues that arise to be addressed in an efficient and methodical manner. Based on the performance of the pilot, Forsta engineers knew, that once optimized to the conditions, the full-scale units would solve the crippling issues of the previously failed strainers.

The secondary clarifiers which feed the trains to the UF system at the Carlsbad facility are open to the air, and as such accumulate debris from the marine environment. The marine debris and the treatment minerals used in the process stream caused some unforeseen issues with the scaled-up cleaning mechanism and piston interface.

When the issues presented themselves, Forsta provided the OEM with a hands-on material adjustment phase, as part of the standard installation optimization protocol. Forsta prides itself on problem solving and making sure that all equipment is set up for success in its environment.

In order to ensure proper and consistent piston function, Forsta engineers introduced a glycol dispenser tank to consistently lubricate the movement of the piston and guarantee that treatment chemicals would not disrupt the mechanical operation of the filters.

After the final material adjustments were made to the full-scale installation, equipment was monitored for a 30-day trial period starting 10/2/17. During the trial period, the bar for performance criteria was set at a 98% minimum recovery rate. The Forsta equipment exceeded the already stringent expectation by demonstrating a 99.9% recovery rate, and a consistent backwash interval of approximately 1x every 45 mins. The cleaning mechanism reliably relieved the differential pressure.

Based on successful operation over a 30-day period, the operators were able to establish a 1x per month routine check of glycol levels on the piston tanks. The strainers passed the 30-day performance test, and equipment has performed consistently ever since (~7 months). The UF system has been able to function at 100% flow capacity and the strainer replacement project has been deemed a success by the OEM and the City of Carlsbad.

CONCLUSIONS: Equipment Selection and Manufacturer Support Bear Greatest Weight

Candlestick backwash strainers proved to be a poor fit for secondary effluent filtration. At the Carlsbad Water Reclamation Facility, when the candlestick strainer manufacturer was contacted for support to troubleshoot failing equipment, no solutions were provided.

In contrast, Forsta Filters provided self-cleaning suction scanners capable of consistent and reliable operation in the conditions presented by the secondary effluent. Forsta demonstrated the reliability of its technology for secondary effluent filtration applications, and the commitment of its engineers to make any system calibrations required to optimize the filters to the environment

As seen in Water & Water Wastes Digest January 2019 issue

CASE STUDY – RIVER WATER FILTRATION:

Forsta Self-Cleaning Filter Protects Vineyard Irrigation System; Contributes to Water Efficiency

Vivác Winery is the creation of brothers Jesse and Chris Padberg, along with their wives, Michele and Liliana Padberg, respectively. In November of 1998 Jesse and Chris embarked on a new mission “to make the best wine possible and have a good time doing it!” This meant professionally crafted, world-ranked, dry red wines-a first for New Mexico.

By choosing only the highest-quality products-from the best New Mexcio grapes, the most advanced winemaking equipment and processes, real corks, to Riedel logo glasses in the tasting rooms-Vivác is a rarity.

At every turn the Padbergs treat their wines with the utmost care; hand-harvesting & hand-sorting grapes, & even using a gentle bladder pump & gravity feed so as not to bruise the wines. Only high-quality French oak barriques and stainless steel barrels are used for aging. After bottling, these lightly filtered & fined wines rest for 12 months before they are sold. Every winemaking step is done meticulously by hand.

The ever-expanding Estate Vineyards (3) are farmed organically & keep Northern New Mexico focused on agriculture. In March of 2013, Jesse Padberg was looking for a water filter to protect the Vineyard’s irrigation system. The Vivác Winery pulls irrigation water from the Rio Embudo (Embudo Creek), a tributary of the Rio Grande. The confluence of the two rivers is approximately 1/2 mile from where Vivác draws its irrigation water.

For Vivác it was important not to rely on having an operator on location to monitor a manual filter during irrigation sessions. In other words, they needed their filter to be self- cleaning. Padberg says that he easily found information on the internet about Forsta Self-Cleaning Filters. He found high quality product info on the web, and that led him to contact Forsta Engineers to size a system specific to the Vineyard’s needs.

The irrigation system at Vivác pumps water through a 4” pipe at 30-50psi. Forsta engineers selected a filter that would allow filtration capacity at 200 micron up to 500gpm. The C4-90 model filter with a 200 micron screen would protect the irrigation system, eliminate the need for routine maintenance, and would provide tremendous water savings when compared to a conventional sand filter.

The Rio Embudo /creek water quality varies according to season and weather. 200 micron filtration was recommended to withstand the variability of the source water and to be fine enough to protect the drip and spray nozzle irrigation system (The small orifices of drip systems make them especially vulnerable to clogging).

Once operational, Padberg noted that the filter reaches differential anywhere from every 5 min. to every 3 hours, depending on the quality of water on a given day. Backwash duration is set at 15 seconds, meaning that each backwash of the C4-90 requires just 15gallons.

According to New Mexico state regulations, the winery is allowed 3 acre feet of water per acre per year. The area is a desert, and though some years are better than others, drought is a constant consideration. Utilizing the water efficient method of drip irrigation, combined with spray nozzles allows the Vineyards to make the most of their water.

Padberg explained the irrigation system saying that, “While it is running, the system pumps around 8-10 gallons per second. There are three irrigation zones, each get one hour of water three times per week when it’s really hot. Not an exact science, we mostly play it by ear. If the cover crop starts getting dry, we irrigate. We run 1 sprinkler per 3 plants and a 1 gallon per hour dripper on each plant.”

Adequate filtration of incoming water to an irrigation system is an integral part of that system’s long-term efficiency. Forsta self-cleaning screen filters use, on average, less than 3% of the volume of water required to

backwash a comparable sand media system.

An agricultural operation that combines efficient self-cleaning screen filtration with a drip irrigation system is set-up for long-term water savings and success. Forsta self-cleaning filters protect drip tubing from debris buildup which can reduce energy efficiency. As irrigation piping and drip tubing orifices become smaller due to buildup it takes more energy to pump water through them. By utilizing available system pressure for cleaning, Forsta self-cleaning filters consume a minimal amount of energy.

With the filter operational for nearly three years, Padberg says his experience with Forsta’s equipment has been good. He would recommend Forsta Self-Cleaning Filters to others with similar applications.

Contact Forsta Filters today for the solution to your irrigation water filtration needs.

Polly Stenberg is Director of Sales with Forsta Filters Inc. – A California-based original equipment manufacturer. Stenberg has conducted case study reviews with customers using Forsta self-cleaning filters in drinking water, wastewater, cooling, agricultural/landscape irrigation and industrial process systems. Polly can be reached at 310-837-7177 x 405 or by emailing polly@forstafilters.com www.forstafilters.com

Forsta Filters’ Director of Sales explains why adequate filtration is necessary for even, efficient, and reliable landscape irrigation.

Walk through the sequence of operation of a Forsta 180 series self-cleaning filter.

Watch the 1-minute Forsta Self-Cleaning Filter 90 series screen change.

Forsta engineers are always trying to find ways to improve the robustness of typical wear parts. Research is conducted on filters in test conditions that simulate the most adverse real-world operating environments. The in-house testing has the goal of ongoing R & D to contribute to design upgrades. By subjecting equipment to the harshest environments possible, engineers are able to design for long-lasting component life. Test units are operated in a high pressure, high solids system using water that contains abrasive particles such as sand and silica. The continuous backwash test guarantees high-performance and durability of filter components even during upset conditions. The rigorous testing is used to ensure that Forsta equipment will not suffer during seasonal/periodic spikes in particle loading that may force the filter into high frequency cleaning.

Walk through an installation checklist at startup on a Forsta D8-LP180 model filter.

MesaAgro Industrial – Puerto Rico

939-338-0607

mesaagro@hotmail.com

mesapr.com

SOLUCIONES DE FILTRACIÓN – SISTEMAS DE TODOS TAMAÑOS

MesaAgro Industrial – Puerto Rico

939-338-0607

mesaagro@hotmail.com

mesapr.com

SOLUCIONES DE FILTRACIÓN – SISTEMAS DE TODOS TAMAÑOS

Preview a variety of Forsta’s expanded 180 Series installations

Preview some of Forsta’s worldwide 180 Series self-cleaning filter installations.

View Forsta Filters’ range of skid-mounted filtration systems.