Precision Engineering & Robust Component Design

Forsta Filters, Inc.

PRODUCT QUALITY

Based on years of hands-on experience and mechanical training,

Forsta engineers design components for smooth integration and robust operating lifespans.

Simple Integration

Care has been taken to simplify installation and service with many models boasting unique access points that minimize the need for dismantling large amounts of equipment. Forsta self-cleaning filters have components that are optimized in material for their environment and range from carbon steel to titanium – depending on the requirement.

Simplified Installation

Minimal Dismantling

Customized to Environment

Rigorous Testing

Forsta engineers are always trying to find ways to improve the robustness of typical wear parts. Research is conducted on filters in test conditions that simulate the most adverse real-world operating environments. The in-house testing has the goal of ongoing R & D to contribute to design upgrades.

Real-world Operating Environments

Harshest Environments

Continuous Backwash

Sustainability

Water Savings

Efforts to use water more sustainably have led to a focus on conservation and efficiency. Infrastructure upgrades are continually improving water efficiency across the industrial, municipal and agricultural sectors. These advancements include the optimization of cooling towers and cooling tower filtration, recycling of sample water at cooling towers and implementation of closed loop water systems involving water reclamation and reuse systems. Forsta industrial water filters play an integral role in the performance of closed-loop systems by protecting equipment and ensuring uninterrupted flow.

Waste water treatment plants and pumping stations can connect (often through thousands of feet of reclaimed water pipes) to storage tanks, chillers, steam boilers and irrigation sites. Reclamation and reuse systems make highly treated or “reclaimed” wastewater available to meet a variety of non-drinking water needs thereby reducing strain on drinking water reservoirs and water treatment plants. Forsta self-cleaning water filters using the point of suction backwash technology provide the industry’s most efficient water filter.

430 Gallons

3 Tank Sand Media Filter System

10 Gallons

C4-90 Self-Cleaning Filter

430% Water Savings

Improving water efficiency can be as simple as replacing a wasteful sand media filter with a self-cleaning screen filter (where feed water quality allows.)

Material longevity

304 and 316L stainless steel are highly durable and long-lasting materials known for their high resistance to corrosion and oxidation. This makes it ideal for use in environments that are subject to moisture, humidity, and other corrosive elements. With proper care and maintenance, 304 and 316L stainless steel can maintain their structural integrity and resist corrosion for several decades, even in harsh and demanding conditions. The exact lifespan of 304/316L stainless steel will depend on a range of factors, including the specific environment and application it’s used in, the level of care and maintenance it receives, and the stresses and strains it is subjected to over time. However, 304/316L stainless steel are highly durable and long-lasting materials that are valued for their reliability, strength, and resistance to corrosion.

We use factory grade 304 and 316L stainless steel to ensure no corrosion or oxidation occurs within the chambers of the filter. As a step further, we offer higher grade alloys in Fiberglass Reinforced Plastic 180 series filter bodies. Being a mixture of glass fibers and polymer matrix, such as polyester, epoxy, or vinyl ester, these filter bodies add additional strength, stiffness and durability compared to 304 and 316L. The glass fibers are woven and chopped up E-glass or S-glass mixed in with the polymer matrix thus granting the extra rigidity. Coating our FRP series is a UV stabilizer to protect the material from effects of sunlight as well as fire retardants to keep high resistance against flames and high temperatures. Our filters are built with the highest grade material to ensure you the cleanest water with the ease of installation and service. Whether it be stainless steel or FRP, each filter body will last decades with very little service needed.

Maximize Equipment Lifetime

Never have a problem with corrosion or oxidation again with our 304/316L Stainless or upgraded Fiberglass Reinforced Plastic Forsta Filters.

Sustainability

Efforts to use water more sustainably have led to a focus on conservation and efficiency. Infrastructure upgrades are continually improving water efficiency across the industrial, municipal and agricultural sectors. These advancements include the optimization of cooling towers and cooling tower filtration, recycling of sample water at cooling towers and implementation of closed loop water systems involving water reclamation and reuse systems. Forsta industrial water filters play an integral role in the performance of closed-loop systems by protecting equipment and ensuring uninterrupted flow.

Waste water treatment plants and pumping stations can connect (often through thousands of feet of reclaimed water pipes) to storage tanks, chillers, steam boilers and irrigation sites. Reclamation and reuse systems make highly treated or “reclaimed” wastewater available to meet a variety of non-drinking water needs thereby reducing strain on drinking water reservoirs and water treatment plants. Forsta self-cleaning water filters using the point of suction backwash technology provide the industry’s most efficient water filter.

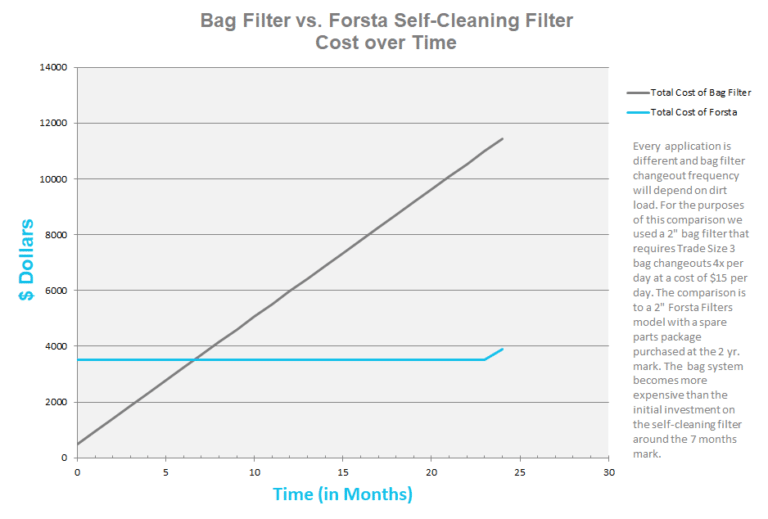

Improving water efficiency can be as simple as replacing a wasteful sand media filter with a self-cleaning screen filter (where feed water quality allows.) Click on the chart below to see a quick and easy-to-read comparison based on a 300gpm flow with 50micron filtration.

Price Quote

Find out what Forsta can do for you

A price quote is always free. It requires no obligation and is good for 30 days.

Just fill out this form.