View This Case Study as a PDF

Automatic self-cleaning water filters are an essential part of water treatment systems across industries, including cooling water systems, drinking water processing, and food and beverage production. A key consideration in these systems is selecting the appropriate screen size, measured in microns, to match the water source and operational requirements. This article explores the significance of the 100–500 micron particle size range, how high-quality screens are fabricated, and real-world applications, such as in a high-volume bakery.

Understanding Micron Screen Sizes and Their Impact

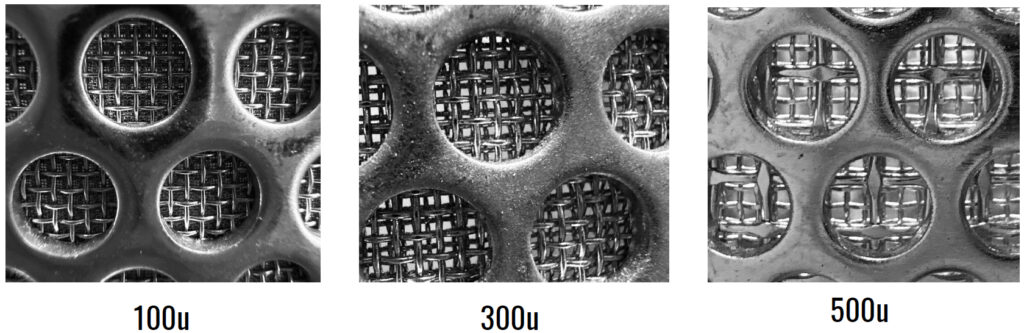

The micron rating of a filter screen determines the size of particles it can remove. Particles in the 100–500 micron range, such as fine sand, silt, organic debris, and certain biological contaminants, are particularly problematic for cooling water systems and other industrial processes.

The micron rating of a filter screen determines the size of particles it can remove. Particles in the 100–500 micron range, such as fine sand, silt, organic debris, and certain biological contaminants, are particularly problematic for cooling water systems and other industrial processes.

Particles in the 100–500-micron range present a diverse array of characteristics that pose challenges for filtration systems. These particles can vary significantly in shape, from angular and irregular (e.g., sand and silt) to rounded and smooth (e.g., pollen or organic debris). Their chemical composition often includes mineral-based hard particles, such as silica and calcium carbonate, as well as softer organic matter like plant fibers and biofilm fragments. The hardness or softness of these particles impacts their abrasiveness and their tendency to deform under pressure, influencing their interaction with filter screens.

Particles in the 100–500-micron range present a diverse array of characteristics that pose challenges for filtration systems. These particles can vary significantly in shape, from angular and irregular (e.g., sand and silt) to rounded and smooth (e.g., pollen or organic debris). Their chemical composition often includes mineral-based hard particles, such as silica and calcium carbonate, as well as softer organic matter like plant fibers and biofilm fragments. The hardness or softness of these particles impacts their abrasiveness and their tendency to deform under pressure, influencing their interaction with filter screens.

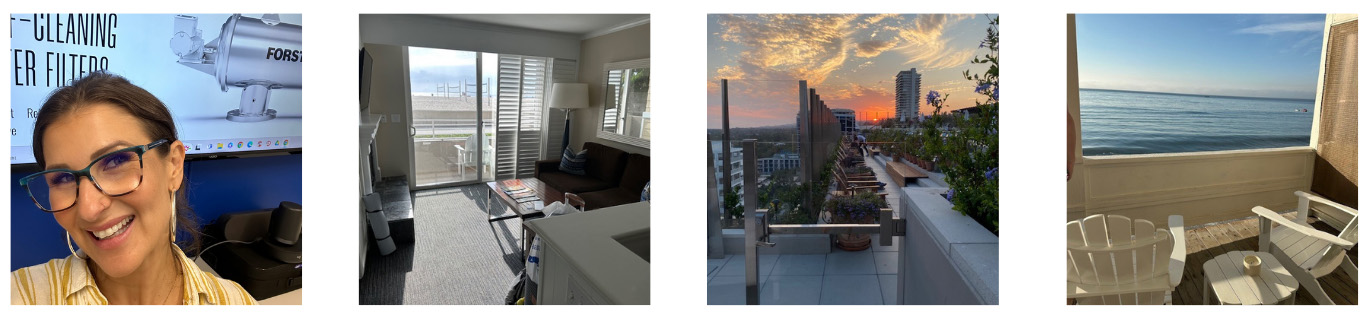

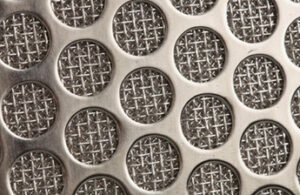

Forsta’s mesh screens are engineered with a multi-layer diffusion-bonded construction, precisely maintaining pore geometry to act as a mechanical barrier that effectively captures particles larger than the rated size. The screen’s smooth surface and uniform aperture design minimize the chances of particle embedding, which optimizes filtration efficiency and facilitates easy removal of debris during the suction cleaning cycle. This geometry ensures a balance between strong particle retention and low resistance to the cleaning process, enabling high filtration performance and extended screen lifespan.

Fabrication of High-Performance Filter Screens

The performance of a self-cleaning filter depends heavily on the quality of its screen. Multi-layer, diffusion-bonded sintered mesh on perforated plate is the gold standard for producing durable, high-efficiency screens. This fabrication method involves:

- Layered Mesh Construction: Multiple layers of stainless steel are stacked to create a strong, uniform filtration surface.

- Diffusion Bonding: Heat and pressure are applied to fuse the mesh layers at the molecular level, eliminating weak points and creating a seamless, robust structure.

- Precision Aperture Control: The bonding process ensures precise and consistent pore sizes, enabling the screen to reliably block particles larger than its micron rating.

Screens produced using this method achieve over 98% efficiency in removing particles larger than their rated size, ensuring dependable protection for water systems.

The perforated plate in the construction of a multi-layer diffusion-bonded mesh screen serves as a structural support layer that enhances the overall durability and performance of the filter. Positioned as the outermost layer, the perforated plate provides mechanical strength to withstand high pressures and flow rates while maintaining the integrity of the finer mesh layers. Its perforations are carefully designed to ensure minimal obstruction to flow while evenly distributing mechanical loads across the mesh. This support helps the bonded mesh maintain its precise aperture size, preventing deformation and ensuring consistent particle filtration efficiency over time. Additionally, the perforated plate aids in the backwashing or suction cleaning process, creating a stable foundation for debris removal without compromising the screen’s performance.

Wedge Wire Screens for Fibers

Wedge wire screens are an excellent alternative for filtering fibrous particles due to their unique V-shaped profile and high structural integrity. The design prevents particle clogging by allowing fibers to slide off the screen surface, ensuring consistent flow and reducing maintenance needs. With precise slot openings, wedge wire screens can effectively capture fibrous debris while offering superior durability and resistance to wear, making them ideal for challenging filtration environments such as pulp, paper, and wastewater applications.

Wedge wire screens are an excellent alternative for filtering fibrous particles due to their unique V-shaped profile and high structural integrity. The design prevents particle clogging by allowing fibers to slide off the screen surface, ensuring consistent flow and reducing maintenance needs. With precise slot openings, wedge wire screens can effectively capture fibrous debris while offering superior durability and resistance to wear, making them ideal for challenging filtration environments such as pulp, paper, and wastewater applications.

Particles in the 100-500U Range Can:

Cause Equipment Fouling: Particles can accumulate on heat exchanger surfaces, reducing efficiency and increasing energy consumption.

Cause Equipment Fouling: Particles can accumulate on heat exchanger surfaces, reducing efficiency and increasing energy consumption.- Promote Biological Growth: Organic matter in this range can serve as a nutrient source for biofilms, leading to microbial fouling.

- Accelerate Corrosion: Sediments can create localized corrosion zones on equipment surfaces.

By effectively removing particles in this range, automatic self-cleaning water filters help maintain system efficiency, reduce maintenance costs, and extend the life of downstream equipment.

Screen Selection and TSS

Screen selection in self-cleaning water filtration systems is guided by the concentration of total suspended solids (TSS) in the water, expressed in parts per million (ppm). For example, a 100-micron stainless steel sintered mesh screen is ideal for water containing < 100 ppm TSS. This alignment ensures that the filter efficiently captures particles without becoming overloaded, maintaining optimal flow and reducing maintenance needs. The overall recommended maximum for TSS for self-cleaning screen filters is 150ppm.

Screens & Particles in the 100-500U Range

Certified Excellence: Use in Food Beverage & Drinking Water Systems

Forsta Filters is a trusted name in automatic self-cleaning water filtration, offering solutions certified by NSF for use in drinking water systems and the food and beverage industry. These certifications ensure that Forsta products meet strict safety and hygiene standards, making them ideal for applications where water quality is paramount.

Engineered for durability and versatility, Forsta Self-Cleaning Filters can operate in high-temperature environments up to 250°F, making them suitable for challenging industrial processes, such as those in bakeries and food production facilities.

In large-scale bakery operations, clean hot water is critical for ensuring sanitary conditions throughout the production process, including mixing, dough preparation, and cleaning equipment. Hot water at precise temperatures helps dissolve fats and sugars while preventing bacterial growth, which is essential for food safety and product consistency. Reliable filtration systems are vital to maintain water purity, particularly when reusing hot water in high-demand environments, ensuring compliance with industry hygiene standards.

In large-scale bakery operations, clean hot water is critical for ensuring sanitary conditions throughout the production process, including mixing, dough preparation, and cleaning equipment. Hot water at precise temperatures helps dissolve fats and sugars while preventing bacterial growth, which is essential for food safety and product consistency. Reliable filtration systems are vital to maintain water purity, particularly when reusing hot water in high-demand environments, ensuring compliance with industry hygiene standards.

Real World Application: A High Volume Bakery Case Study

Forsta filters’ effectiveness can be seen in a high-volume bakery that produces hundreds of thousands of baked goods daily. The bakery utilizes two Forsta B-90 model filters for hot tank water filtration. These filters ensure a steady supply of high-quality sanitary water at elevated temperatures, crucial for maintaining hygiene and product quality.

Forsta filters’ effectiveness can be seen in a high-volume bakery that produces hundreds of thousands of baked goods daily. The bakery utilizes two Forsta B-90 model filters for hot tank water filtration. These filters ensure a steady supply of high-quality sanitary water at elevated temperatures, crucial for maintaining hygiene and product quality.

The B-90 filters are equipped with 200-micron screens, optimized for removing particles like flour dust, minor organic debris, and sediment from the water supply. The self-cleaning mechanism eliminates the need for manual intervention, providing the bakery with uninterrupted operation and significant labor savings.

Switching to a system delivering 600 gallons per minute (GPM) of reliable flow from a hot water tank has dramatically improved efficiency in the bakery compared to the previous use of conventional filters. The automated filtration system eliminates the frequent downtime associated with replacing and disposing of bag filters, saving labor costs and reducing process interruptions. Additionally, the self-cleaning mechanism prevents water waste, recirculating filtered water back into the system, which significantly lowers water consumption. Energy efficiency has improved as well since maintaining a consistent flow from the hot water tank reduces the need to reheat water lost during manual filtration. Overall, the bakery has saved thousands of dollars annually in operational costs while achieving more consistent production schedules and enhanced sustainability.

Whether for a high-volume bakery or a complex cooling system, Forsta Self-Cleaning Filters exemplify how the right technology can enhance efficiency and ensure operational excellence.

A basic introduction to Forsta Self-Cleaning Filters

Enhancing Water Quality in Hospitality

In today’s hospitality industry, ensuring high-quality amenities and services is paramount to maintaining customer satisfaction and loyalty. Among these amenities, access to clean and safe water stands out as a fundamental necessity for guests. Implementing point-of-entry filtration systems in hotels can significantly enhance water quality, thereby elevating the overall guest experience. This analysis advocates for the adoption of point-of-entry filtration systems in hotels, using the Greater Los Angeles area as a case study, and extrapolating its significance to cities like Mexico City. The study also discusses the unique challenges of the hotel industry in island contexts.

Greater Los Angeles Area, California

Water quality in the Greater Los Angeles area has long been a topic of concern due to various factors such as industrial pollution, urban runoff, and aging infrastructure. Suspended solids, including sediment, organic matter, and other particles, can be present in water sources throughout the region. These solids can affect water quality, causing issues such as turbidity, taste, and odor problems, as well as potentially harboring harmful microorganisms.

Water quality in the Greater Los Angeles area has long been a topic of concern due to various factors such as industrial pollution, urban runoff, and aging infrastructure. Suspended solids, including sediment, organic matter, and other particles, can be present in water sources throughout the region. These solids can affect water quality, causing issues such as turbidity, taste, and odor problems, as well as potentially harboring harmful microorganisms.

Hotel Industry in Los Angeles

The Greater Los Angeles area boasts a vibrant hotel industry, accommodating millions of visitors annually. According to recent data, the Los Angeles area is home to over 1,000 hotels, catering to a diverse range of clientele. Among these establishments, a substantial portion comprises luxury hotels renowned for their exceptional service standards and upscale amenities.

High Volumes of Water Are More Likely to Contain Suspended Solids

The high volume of water used in hotels compared to small residences significantly increases the likelihood of suspended solids being introduced into the water supply.

The high volume of water used in hotels compared to small residences significantly increases the likelihood of suspended solids being introduced into the water supply.

In the absence of point-of-entry filtration systems in commercial buildings, water in the Greater Los Angeles area may indeed carry small amounts of suspended solids. These solids can originate from a variety of sources, including natural erosion, construction activities, and runoff from roads and urban areas. Additionally, old and deteriorating pipes in the water distribution system can contribute to sediment buildup and contamination.

Given the importance of clean and safe water for hotel visitors, it has become increasingly recognized as a best practice to install self-cleaning filters at the point of entry, particularly in establishments such as hotels. These filters are designed to remove suspended solids from the water as it enters the building, ensuring that guests have access to high-quality water for drinking, bathing, and other uses.

The high volume of water used in hotels compared to small residences significantly increases the likelihood of suspended solids being introduced into the water supply. There are several reasons why this is the case:

Increased Water Flow

Hotels typically have a much higher water demand than small residences due to the large number of guests, multiple floors, and numerous amenities such as swimming pools, spas, and laundry facilities. The higher water flow rates result in greater turbulence within the plumbing system, which can stir up sediment and suspended solids that may have settled in the pipes.

Complex Plumbing Systems

Hotels often have more complex plumbing systems with extensive networks of pipes, valves, and fixtures spread across multiple floors and wings. These systems provide more opportunities for sediment accumulation, especially in areas with low flow or stagnant water, such as unused guest rooms or infrequently used bathrooms.

Variety of Water Sources

Hotels may source water from multiple suppliers or groundwater wells, each with its own characteristics and potential for contamination. Additionally, water may be stored in large tanks or reservoirs on-site before being distributed throughout the building, providing additional opportunities for sedimentation and the introduction of suspended solids.

High Turnover of Guests & Activities

Hotels experience frequent turnover of guests and activities, resulting in fluctuating water usage patterns throughout the day. As guests shower, bathe, flush toilets, and use other amenities, they can inadvertently introduce particles such as dirt, hair, and soap scum into the water supply, further contributing to the presence of suspended solids.

Maintenance Challenges

Maintaining water quality in a large hotel can be challenging due to the scale and complexity of the infrastructure. Regular maintenance tasks such as flushing pipes, cleaning storage tanks, and replacing filters may be more difficult to perform consistently, increasing the risk of sediment buildup and contamination.

Research: Thoughts on Hospitality & The Guest Experience

Over the past several years, my professional research journey as the Director of Sales with Forsta Filters has taken me through the diverse landscape of hotels in Los Angeles. What better place to deepen my understanding of an evolving industry than in my own backyard? From the shores of LA’s beach city resorts to the vibrant pulse of downtown accommodations, each hotel has woven its own unique narrative into my exploration of water use in this dynamic city.

At a chic boutique hotel nestled along the iconic Venice Beach, property design effortlessly blended with the surroundings, echoing the laid-back vibe of its coastal locale. However, what struck me most was the commitment to sustainability, evident in every aspect of the guest experience. From eco-friendly amenities to water-saving initiatives, it was clear that preserving the precious resource of clean water was central to their ethos.

Contrastingly, stays in downtown Los Angeles offer a glimpse into the city’s bustling energy and rich cultural tapestry. Here, amidst the towering skyscrapers and bustling streets, I found myself immersed in a world of urban sophistication. Yet, even in the heart of the city, the importance of clean water remained paramount. Whether enjoying a revitalizing shower after a day of exploration or indulging in a refreshing drink at the hotel bar, the quality of water directly impacted the overall guest experience.

In the midst of my exploration of hotels throughout Los Angeles, my journey inevitably led me to the glitz and glamour of Hollywood. Here, amidst the legendary landmarks and star-studded sidewalks, hotels take on a character all their own. From iconic establishments frequented by silver screen legends to modern boutique gems, each property exudes its own brand of cinematic charm. Yet, regardless of their star-studded status, one thing remains constant: the importance of clean water in shaping the guest experience. Whether basking in the luxury of a rooftop pool overlooking the Hollywood Hills or preparing for a red-carpet event in a lavish suite, access to pristine water is integral to the allure of these Hollywood havens. As I immersed myself in the opulence of Hollywood’s hospitality scene, I gained a deeper appreciation for the intricate interplay between glamour and sustainability, further reinforcing the significance of maintaining water quality standards across all facets of the industry.

As a water industry professional, my experiences in these hotels has provided invaluable insights into the intricate relationship between hospitality and water management. Observing firsthand the measures taken to ensure sustainability and water conservation underscored the vital role that clean water plays in the guest experience. My experiences serve as a constant reminder of the ongoing challenges and demands facing the water industry. By staying connected to the guest experience, I am better equipped to address industry standards and anticipate evolving demands, ultimately contributing to the seamless operation of hotels.

Throughout my stays at various hotels in Los Angeles, and anywhere I travel, I have made it a personal mission to not only enjoy the amenities and ambiance but also to connect with the people behind the scenes. Whenever I check in to a hotel, I take the opportunity to introduce myself and share a bit about my unconventional career path, which took me from waitressing to the realm of water filtration. Engaging in casual conversations with hotel staff and fellow guests, I often find myself delving into discussions about the intersection of technology and personal relationships within the water industry.

Sharing my journey from hospitality to water filtration often sparks curiosity and intrigue among those I encounter. Whether chatting with the concierge about the importance of sustainable practices or striking up a conversation with fellow travelers at a hotel bar, I consistently find that my passion for connecting with people transcends the boundaries of my professional background. Through my real-life interactions, I consistently discover a shared appreciation for the human element within the realm of technological innovation.

Being immersed in the hospitality environment serves as a constant reminder of why I was drawn to the field of water filtration in the first place. Beyond the intricacies of water treatment processes and technological advancements, my true passion lay in forging meaningful connections and fostering relationships that would humanize the often complex world of water management. By infusing the technological side of water filtration with a personal touch, It is always my hope to bridge the gap between industry expertise and everyday experiences, making the importance of clean water more tangible and relatable to all.

As I continue my journey through the diverse landscape of Los Angeles hotels, each encounter reinforces my belief in the power of conversation and connection to drive positive change within the water industry. Whether sharing anecdotes about my career trajectory or simply engaging in casual banter with fellow travelers, I am reminded that at the heart of it all, the essence of hospitality lies in the art of genuine human interaction. From the boardroom to the rooftop bar, it is through relationships that we can truly make a difference, one conversation at a time.

Water Consumption in Hotels

Hotels are significant consumers of water due to various operational needs, including guest amenities, housekeeping, and food service. On average, a mid-sized hotel in the Greater Los Angeles area consumes approximately 3,000 to 5,000 gallons of water per day. Considering the multitude of hotels in the region, the collective water consumption is substantial, underlining the importance of efficient water management practices.

Importance of Point-of-Entry Filtration

Point-of-entry filtration systems serve as the first line of defense against contaminants entering a hotel’s water supply. Self-cleaning filters, in particular, offer numerous advantages in maintaining water quality. By installing self-cleaning filters at the point of entry, hotels can safeguard the incoming water supply from pipe scale, sediment, and other debris that may accumulate during transit from the central water treatment plant.

Advantages of Self-Cleaning Filters

Self-cleaning filters are designed to automatically remove impurities from the water without requiring manual intervention. Self-Cleaning filters utilize an automatic backwash sequence to eliminate accumulated debris, ensuring continuous filtration efficiency. Additionally, self-cleaning filters offer long-term cost savings by reducing maintenance requirements and prolonging the lifespan of downstream equipment.

Energy Efficiency Benefits

Adequate filtration also contributes to energy efficiency in hotel operations. Without proper filtration, pipes can accumulate scale over time, leading to reduced pipe orifice and increased frictional resistance. As a result, more energy is required to pump the same amount of water through the system. By preventing scale buildup, self-cleaning filters help maintain optimal flow rates, thereby minimizing energy consumption and operational costs for hotels.

Challenges in Older Parts of Los Angeles

While Los Angeles has undergone extensive development, certain neighborhoods, particularly in older parts of the city, may have aging infrastructure, including water distribution systems. Hotels situated in these areas are more likely to encounter issues related to deteriorating pipes and increased susceptibility to contaminants.

Application in the Greater Los Angeles Area

In the Greater Los Angeles area, hotels rely on a centralized water distribution network supplied by municipal water authorities. While the water undergoes treatment at the source, the aging infrastructure poses risks of contamination during transit. By installing self-cleaning filters at the point of entry, hotels can mitigate these risks and guarantee pristine water quality for guests, especially in neighborhoods with aging infrastructure.

Regional Case Study: Hyatt Regency, Mexico City

Hyatt Regency Mexico City is in the heart of the Polanco neighborhood. They boast 755 pristine hotel rooms, including 18 suites, with lovely views of Chapultepec Park, the city and the mountains at the horizon.

Mexico City, akin to Los Angeles, faces challenges related to water quality and distribution due to its dense urban population and aging infrastructure. By extrapolating the concepts of point-of-entry filtration from city to city, hotels can emulate effective strategies to enhance water quality and uphold guest satisfaction.

Forsta C3-90 and B2-90 Filters, 25u

Forsta C3-90 and B2-90 Filters, 25u

Forsta FIlters partnered with Helguera Technologies Del Agua in order to work directly with the Hyatt Hotel’s maintenance manager. Together we designed a 3 filter system for inlet flows of 110 and 200gpm to provide fine screen filtration for water entering the hotel.

The Lesson From Schools: New York City

Potable Water Filtration Systems

Forsta self-cleaning filters prevent the introduction of rust and pipe scale into drinking water systems, and provide efficient and reliable water quality regulation in accordance with NSF drinking water requirements.

The New York City School Construction Authority now requires that all potable water filtration systems be equipped with point-of-entry filters. Forsta A4-LP180C model filters are widely used throughout the city for this purpose. From Queens to the Bronx to Staten Island, Forsta Self-Cleaning Filters are ensuring that clean water enters the building in New York City’s schools.

90 Series Filters

Shown at right: (2) C4-90 model filters with 25 micron screens on a stainless steel manifold. These NSF-61 certified filters are installed in a custom configuration to meet the point-of-entry filtration requirements

LP180C Series Filters

LP180C Series Filters

Shown at Left: The Forsta A4-LP180C model filter with 25 micron screen and custom manifold was successfully installed on the potable water line at PS70R to prevent suspended solids from entering the school’s potable water system.

Filtration for Hotels on Islands

Point-of-Entry Filtration for Hotels on Islands

In island destinations where tourism plays a pivotal role in the economy, ensuring the availability of clean and safe water for hotels is paramount to maintaining visitor satisfaction and promoting sustainable development. However, producing large volumes of potable water in island contexts presents unique challenges that require innovative solutions to address.

Challenges of Producing Potable Water on Islands

Limited Water Resources: Many islands have limited freshwater resources, relying heavily on rainfall, surface water, groundwater, and packaged desalination plants for their water supply. High demand from both residents and tourists can strain these resources, leading to issues such as saltwater intrusion, groundwater depletion, and contamination from runoff and pollution.

Vulnerability to Climate Change

Island communities are particularly vulnerable to the impacts of climate change, including rising sea levels, changing rainfall patterns, and more frequent extreme weather events. These factors can exacerbate water scarcity and quality issues, affecting both the availability and reliability of water supplies for hotels and other businesses.

Isolation and Logistics

Islands often face logistical challenges in transporting equipment, supplies, and personnel, which can hinder the implementation of large-scale water treatment and distribution infrastructure projects. Limited access to specialized expertise and resources may further complicate efforts to address water quality issues effectively.

Retrofitting Pump Rooms with Self-Cleaning Filters

To mitigate the risks associated with particulate matter entering the water supply, existing hotels on islands are increasingly turning to retrofitting their pump rooms with self-cleaning filters as an additional safeguard. These filters are designed to remove suspended solids, sediment, and other contaminants from the water before it enters the hotel’s distribution system, ensuring that guests have access to clean and safe water for drinking, bathing, and other purposes.

Forsta FRP Series

The Forsta 180 Fiberglass Reinforced Plastic Series filters offer an ideal solution for corrosion resistance in brackish, brine and seawater applications. All wetted components of the FRP Series filters are constructed from seawater-resistant materials.

Island Challenges: Santorini, Greece

Challenges of Producing Potable Water on Islands

Producing potable water for hotels on Santorini Island presents a unique set of challenges due to the island’s geographical characteristics and limited water resources. With its arid climate and porous volcanic soil, Santorini faces scarcity in freshwater sources, relying heavily on desalination and groundwater extraction. However, the influx of tourists during peak seasons strains the already limited water supply, necessitating innovative solutions for water conservation and management. Hotels must implement advanced desalination technologies and water recycling systems to meet the demands of guests while preserving the fragile ecosystem of the island. Balancing the needs of hospitality with sustainable water practices remains an ongoing challenge, highlighting the importance of proactive measures to ensure the long-term viability of Santorini’s water supply

Packaged Desalination Plants

Package desalination plants play a crucial role in addressing Santorini Island’s water challenges by providing a decentralized solution to freshwater production. These compact, modular units offer flexibility in installation and operation, making them ideal for catering to the needs of hotels and resorts scattered across the island.

Resilience Against Water Scarcity

By harnessing the abundant seawater surrounding Santorini, package desalination plants utilize advanced membrane technology to convert saline water into potable water, ensuring a reliable and sustainable water supply for hospitality establishments. Their scalability and efficiency enable hotels to mitigate the strain on local freshwater sources while adapting to fluctuating demand during peak tourist seasons. As a key component of Santorini’s water infrastructure, package desalination plants contribute to the island’s resilience in the face of water scarcity, supporting its thriving tourism industry while safeguarding its precious natural resources.

Opportunity for Improvement

The opportunity to enhance package desalination plants by replacing traditional cartridge filters with self- cleaning filters presents a significant area of advancement in water treatment technology. Integrating self- cleaning filters into package desalination plants, will reduce maintenance requirements and improve operational efficiency, particularly in remote or resource-constrained settings like Santorini Island.

Unlike cartridge filters, which require periodic replacement and manual cleaning, self-cleaning filters automatically remove debris and contaminants, ensuring consistent performance and extending the lifespan of desalination equipment. This upgrade not only streamlines maintenance efforts but also enhances the reliability and sustainability of package desalination plants, ultimately contributing to a more resilient and cost-effective solution for providing potable water to hotels and resorts on the island.

Island Challenges: Montego Bay, Jamaica

Future of Filtration

Montego Bay, Jamaica, boasts a vibrant tourism industry with a plethora of hotels catering to visitors from around the globe. With its stunning beaches and lush landscapes, the city is home to a diverse range of accommodations, from luxury resorts to boutique hotels. In this tropical paradise, the use of self-cleaning filters will be paramount for maintaining clean and safe water supplies amidst the challenges of the environment. Centralized water treatment facilities help to ensure that water sourced from rivers or groundwater meets stringent quality standards before being distributed to hotels.

Adding point-of-entry filtration systems within individual hotels will further enhance water quality by removing any solids picked up between the plant at the point of entry into the property’s water infrastructure. Together, these dual approaches to water filtration play a crucial role in ensuring the smooth operation of Montego Bay’s hotel industry, providing guests with the peace of mind that comes with access to clean and refreshing water throughout their stay.

Well Water

Groundwater wells in Jamaica serve as a vital source of potable water, especially in areas where surface water may be limited or unreliable. Through sustainable management practices, these wells provide essential freshwater resources, supporting both local communities and the tourism industry across the island. Forsta partners with local agencies like Jamaica Wells & Services in the ongoing advancement of efficient technology on the island, both at the point of extraction or the point-of entry.

Island Challenges: Phuket, Thailand

Tourism and Increasing Urbanization

In Phuket and throughout Thailand, the production of potable water is a critical endeavor, especially in the face of increasing urbanization and tourism. With a reliance on surface water sources such as rivers and reservoirs, coupled with the challenges of pollution and climate change, ensuring a safe and sustainable water supply remains a pressing concern. Additionally, rapid population growth and development exacerbate the strain on existing water resources, highlighting the need for innovative solutions. The implementation of self-cleaning filters, offers a cost-effective and efficient means of maintaining water quality in decentralized systems.

Improved Reliability

By automating the filtration process and reducing the need for manual maintenance, self-cleaning filters can improve the reliability and longevity of water treatment infrastructure, even in the most remote of locations, ultimately enhancing the resilience of Thailand’s potable water supply in the face of evolving challenges. As the country continues to prioritize sustainable water management practices, the widespread adoption of self-cleaning filters represents a promising step towards a more resilient and water-secure future for Phuket and beyond Forsta works with regional partners in the ongoing advancement of efficient technology on the island, both at the point of extraction or the point-of entry.

View This Case Study as a PDF

FORSTA SELF-CLEANING FILTERS PROVIDE RELIABLE FILTRATION ON COOLING WATER; 26,000+ GALLONS PER MINUTE AT THE OAK RIDGE NATIONAL LABORATORY

Cooling tower water filters in the new mechanical room for the OLCF’s upcoming Frontier exascale computer.

Keeping debris, scale and biological growth out of a computer or data center’s cooling system is critical to maintaining energy efficiency, conserving water, and providing reliable cooling for the system. The scale of data center cooling requirements can range from several hundred gallons per minute for small cell phone data centers, to many thousands of gallons per minute to cool the world’s fastest high-performance super computers. Forsta self-cleaning filters provide reliable filtration for data cooling systems of all sizes.

OAK RIDGE NATIONAL LABORATORY

The Oak Ridge National Laboratory is home to the U.S. Department of Energy’s Office of Science, the single largest supporter of research in the physical sciences in the United States.When the U.S. Department of Energy’s (DOE’s) new exascale supercomputer, Frontier, completed installation at Oak Ridge National Laboratory (ORNL) in 2021, it debuted as a landmark in high-performance computing with groundbreaking performance of greater than 1.5 exaflops (one quintillion floating-point operations per second). Before the supercomputer could come online, the room it occupies had to undergo a complete mechanical, electrical, and structural transformation.

An article on the lab’s website detailing the process reads;

“Long before the data center’s construction began—even before the demo work to gut the room—another massive building project had to be tackled: a mechanical room for all the machinery that will be feeding cooling to Frontier. The new supercomputer’s cooling water towers will have a system volume of 130,000 gallons, with 350-horsepower pumps that can each move over 5,000 gallons per minute of the high-temperature water through the Frontier system. The four pumps will connect to the data center via 500 linear feet of 24-inch pipe.”[i]

Two Forsta H24-180D model filters dual chamber units with 24” inlet and outlet were selected to handle a maximum flow of 13,000 gallons per minute each and were successfully installed to protect the Frontier cooling system. The 500 micron wedge wire screens remove suspended solids that could cause damage to the cooling system. The wedge wire screens were selected in particular to tackle the challenging environment of airborne particulate, including cottonwood seeds and other fibrous organic matter.

WHY COOLING SYTSEMS NEED FILTRATION

Poor water quality (including high particle loading) can lead to the following common problems within a cooling tower system: corrosion, scaling, fouling and microbiological activity. These problems are inter-dependent to the extent that prevention of one may help reduce the magnitude of the others. An effective filtration system lowers the particulate levels in the cooling water, which directly reduces fouling.

Because microbiological organisms will feed on organic particulates, reduction of particulates also corresponds directly with a reduction in biological growth. It follows that filtration will prevent corrosion that occurs as a result of microbiological growth, and scaling which occurs as a byproduct of fouling and corrosion. Filtration minimizes all the risks associated with cooling tower operation.

Minimizing risk to the world’s fastest supercomputers is a task that Forsta’s equipment fulfills reliably.

[i] https://www.olcf.ornl.gov/2020/12/11/building-an-exascale-class-data-center/

Walk through the basic steps for startup & shutdown of a Forsta 180 Series Self-Cleaning Filter.

An 18-hole championship public golf course carved beautifully out of the rolling Wisconsin countryside was losing up to 20 sprinkler heads a year due to debris in their irrigation system. The stuck heads were disrupting the nightly watering cycle, incurring replacement costs and requiring upwards of 20 man hours a day just for repairs. The cumulative cost to the course was easily $10,000 a year. Learn how the installation of a Forsta self-cleaning water filter in 2010 eliminated these problems and is saving the golf course water, time and money.

When irrigation systems are unprotected, dirt and debris collect in sprinkler nozzles and quickly disrupt spray patterns. Regardless of sprinkler head spacing, clogged nozzles can cause uneven coverage leading to brown patches and severe damage. Left unchecked, clogged nozzles become completely obstructed and must be replaced. This requires regular maintenance, which can be time consuming, disruptive and costly.

It was precisely this type of costly disruption that Marty Van Ells of Municipal Well and Pump wanted to eliminate at the golf course in 2010.

As the project manager for the 18-hole championship public golf course, Van Ells had to solve the issue of irrigation heads sticking due to the large amount of sand coming from the course’s pond water source. Van Ells explained that, “When the heads would get “stuck”, they often had to be replaced due to how cemented the debris was packed into the head. They would lose as many as 20 a year at a replacement cost of several hundred dollars each. In addition, the nightly watering cycle was significantly impacted due the water losses from the stuck heads. Frequently, the entire course would not be completely watered, and they would get many sand trap washouts. On any given morning, they might have 15 heads to clean, or replace, which would cost them upwards of 20 man hours a day just for repairing heads.”

The golf course pump station flows 900gpm in a 6-inch line at 110psi. Based on these parameters, Forsta engineers proposed the B6-180 model filter which would provide 5.25 sq ft of screen area. A 200 micron (70 mesh) screen was selected to protect the sprinkler heads from the sand and other debris that had been disrupting the system.

The B6-180 model filter was installed at the pump discharge in early 2010. The filter was positioned at the discharge of the pump in order to best utilize the available line pressure to power its point-of-suction backwash cycle. This unique approach to backwashing ensured that even while cleaning itself, filtered water would continue to flow. The continuous flow of the Forsta self-cleaning filter eliminated the need for standby filters and complex valve schematics, frequently needed with other types of filters.

The initial installation/case study review was conducted in the latter portion of 2010. When asked how the filter was performing at that time, Van Ells said,

“The filter works awesome! It looks like this is going to be a great success! We’re going to be pushing Forsta Filters for other installations.”

At ~5 years of operation, Forsta conducted an additional installation case study review to follow up on the performance parameters of the filter, and the problems that the golf course had wanted to correct.

Currently, the filter typically backwashes every 15 – 20 minutes in the spring, and once every 30 minutes summer through fall. The filter is set to a 15 second backwash cycle and the flush water returns to the irrigation pond away from the inlet pipe to the pump station.

According to Van Ells, “a quart jar sample of water prior to the filter would typically have a circle of sand about 3-inches in diameter with a lot of vegetation floating in the water. The filtered water truthfully has no visible sand or vegetation in the jar.”

Automatic Success in Irrigation

December 10, 2010

City of Santa Maria, California

Problem:

Suspended particles in well water can be a big problem when it comes to clogging sprinkler heads and creating buildup on pipe walls. Dirty water can lead to equipment failure and forced downtime.

This is the problem that Alex Posada was responsible for solving. Posada is the Director of Recreation & Parks for the City of Santa Maria, California. The challenge before him was to reduce particulate matter from a well at a local recreation open-space park.

“Water being pumped from the well had a significant amount of mineral and soil debris contamination giving the water a cloudy appearance. It was leaving

heavy residue deposits in our pipe lines, water troughs and water tanks.” said Posada.

Solution:

The City of Santa Maria installed a Forsta B2-90 self- cleaning water filter to help remove particles from the well water. The filter’s compact design made installation easy, and the backwash controller now allows the system to be fully automatic, eliminating the need for frequent maintenance.

The 50 micron multi-layer screen traps suspended particles, and expels them when buildup occurs. The point-of-suction backwash cycle cleans the screen without interrupting the system flow. Filtered water is continually supplied to the park’s irrigation system, even when the filter is cleaning itself.

“We are satisfied with the filter we have and it seems to be working well for our application.” Posada said of the Forsta self-cleaning water filter.

When asked about working with Forsta Filters and Application Engineer Eran Fischer, Posada replied, “Eran was very helpful in following up with my emails and our installers got good tech support while installing the system. I would say our experience was very good.”

Forsta 180 Series Self-Cleaning Irrigation and Industrial Water Filter

How it Works

Forsta 90 Series Self-Cleaning Irrigation and Industrial Water Filter

How it Works

Forsta LP180 Series Self-Cleaning Irrigation and Industrial Water Filter

How it Works

RESEARCH/DESIGN/FUNDING: Indian Health Service, Albuquerque Area

OPERATOR: Laguna Pueblo Utility Authority

REQUIREMENT: 24/7 system to remove large debris from the spring water and protect LT2 compliance filters (5μ/1μ)

SYSTEM PARAMETERS: 85-100gpm, 50psi, 2″ Line

DESIGN CONCEPT: Multi-stage filtration, 1000μ, 50μ, 25μ

EQUIPMENT:

According to the EPA, More than 94 percent of the nation’s 156,000 public water systems serve fewer than 3,300 persons. These systems—classified as small by EPA—face unique financial and operational challenges in providing drinking water that meets EPA standards.

In the small community of Encinal Village, New Mexico, a spring-fed water system is the sole source of drinking water. The system is classified by the EPA as schedule 4, and serves approximately 200 persons and 60 homes.

The system is run by the Laguna Pueblo Utility Authority, and operates in compliance with the EPA’s LT2 Enhanced Surface Water Treatment Rule (LT2ESWTR) which provides guidelines for source water monitoring and filtration.

Raw water from the springs nearby Encinal Village had very low turbdity (.05 NTU), but there was concern that strands of grasses and other plant material would shorten the service life of the 5 and 1μ cartridge filters selected for LT2 compliance.

David Steen, P.E., Sr. Field Engineer with the Indian Health Service, wanted to reduce the labor and replacement costs of disposable filters. Steen provided Forsta engineers with a raw water sample from the springs. The sample included fibers and other debris that were negatively affecting the fine cartridges. Results of sample testing would inform the screen selection for a new automatic, self-cleaning filter system to serve as pre-filtration to the finer polishing cartridges.

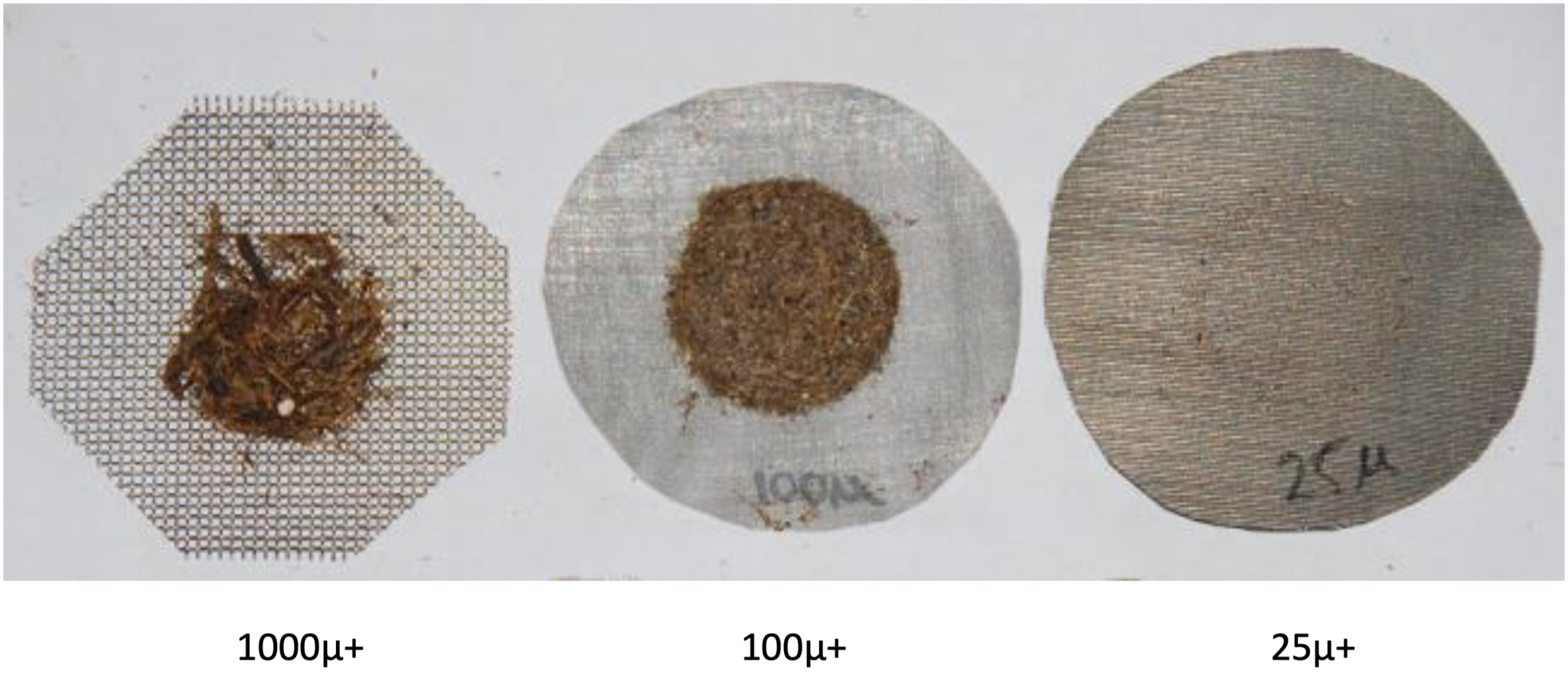

To assess the debris present in the raw spring water, Forsta engineers conducted tests using a descending sequence of screen mesh sizes. The test showed the concentration of debris at select sizes, and also indicated the finest screen appropriate to the Encinal spring water source.

Based on the test results (shown above), Steen selected a three-stage filtration sequence with 1000μ, 100μ and 25μ. The fully automated three-stage plan would provide reliable pre- filtration, extend the service life of the LT2 compliance filters, and reduce maintenance requirements.

The system went online in the summer of 2011. Operating conditions in the field were monitored over the course of several months. Based on an initial review of the flush frequency of each of the filters it was determined that reducing the 100μ screen to a 50μ alternative would help to balance the system.

Forsta engineer Eran Fischer provided an onsite training and installation evaluation to coincide with the screen change out. The simple screen adjustment effectively reduced the workload on the final 25μ filter and streamlined the operation of the system as a whole.

During the installation review Fischer confirmed that each of the filters had sufficient inlet pressure during backwash (min 40psi), minimal back pressure on the flush line, and that differential pressure on each of the filters returned to <1psi after each cleaning cycle was complete.

Flow from the springs remains at a fairly consistent 85-100gpm and the system operates on a 24/7 basis. The 1000μ filter is currently set to backwash once per day on timer. The 50μ filter backwashes twice per day based on pressure differential, and the 25μ filter backwashes once per hour based on pressure differential. Per 24 hour period, the cleaning cycles of the complete filtration system use approximately 216 gallons, with no interruption to system flow during the backwash sequence. Backwash water goes to a drain which feeds into a ditch collection and the irrigation system in the village.

Certified Water & Wastewater Operator Andrew Sweetman has operated the filters for Laguna Pubelo for 3+ years and is also the facility QA/QC Manager. When asked about the Forsta system he noted, “Working with the Forsta equipment has been relatively easy and hassle free. At our installation the filters are readily accessible, compact, easy to isolate for maintenance, and easily dissembled for periodic maintenance.”

Sweetman said that he would highlight the automatic backwash/self-cleaning operation of the filters, use with high pressure flows and the robust nature of the steel screens/filters as benefits of Forsta’s equipment.

In order to examine the particle removal efficiency of the system at four years in operation, Sweetman collected one gallon samples prior to the 1000μ filter (raw spring water) and after the 25μ filter.

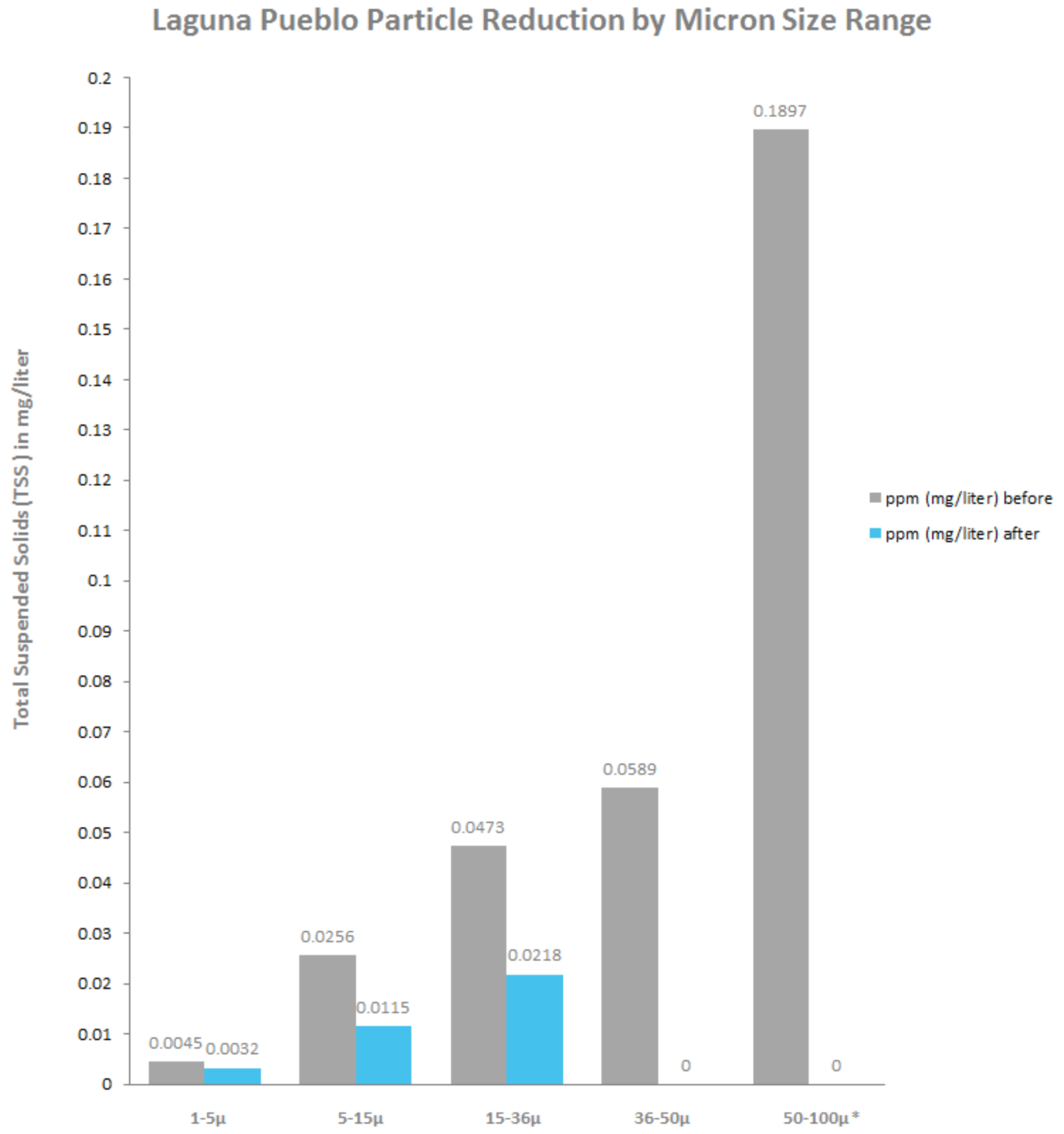

Total Suspended Solids (TSS) was reduced across the three-stage system from .33ppm to .04ppm, for an overall reduction of 88%.

Particle size analysis shows that 100% of particles were removed above the absolute degree of filtration (34-36μ) of the finest screen (25μ).

The analysis also shows a 63% particle reduction in the 1-36μ size range, with particle loading being reduced from .08ppm to .03ppm. Particle removal in this range is due to what has been referred to as “the filter cake effect.” The filter cake effect describes the phenomenon of screen orifices becoming smaller as a screen accumulates dirt.

The graph below depicts the efficiency of Laguna Pueblo’s three-stage filtration system by categorizing particle reduction into micron size ranges.

*TSS values are based on instantaneous samples taken before/upstream of the 1000 micron filter, and after/downstream of the 25 micron filter. ~ 5 anomalous particles were detected in the downstream sample at the 52μ and 82μ size, and are not depicted here. Introduction of these particles to the sample is attributed to a low-control sample collection/ transportation procedure. See full laboratory analysis reports for further reference.

With increasing drought conditions in the Western U.S., efficiency and water conservation is an important consideration for many municipal water systems. According to Steen the output of the springs on this specific system has not decreased. Laguna has however seen some decline in other wells.

In addition to using water efficient technologies like Forsta in their centralized treatment plant, Steen explained that Laguna has started to monitor individual meters and contact homes with suspected leaks.

The reliable and efficient four year operation of Laguna’s three-stage self-cleaning filtration system has saved the water authority an estimated 2-4 cartridge filter replacements per year. This has amounted to reduced costs in equipment and labor.

See the published study at W&WD online:

Polly Stenberg is Director of Sales with Forsta Filters Inc. – A California-based original equipment manufacturer. Stenberg has conducted case study reviews with customers using Forsta self-cleaning filters in drinking water, wastewater, cooling, agricultural/landscape irrigation and industrial process systems. Polly can be reached at 310-837-7177 x 405 or by emailing polly@forstafilters.com www.forstafilters.com

Forsta Industrial and irrigation self-cleaning water filter key performance criteria video